-40%

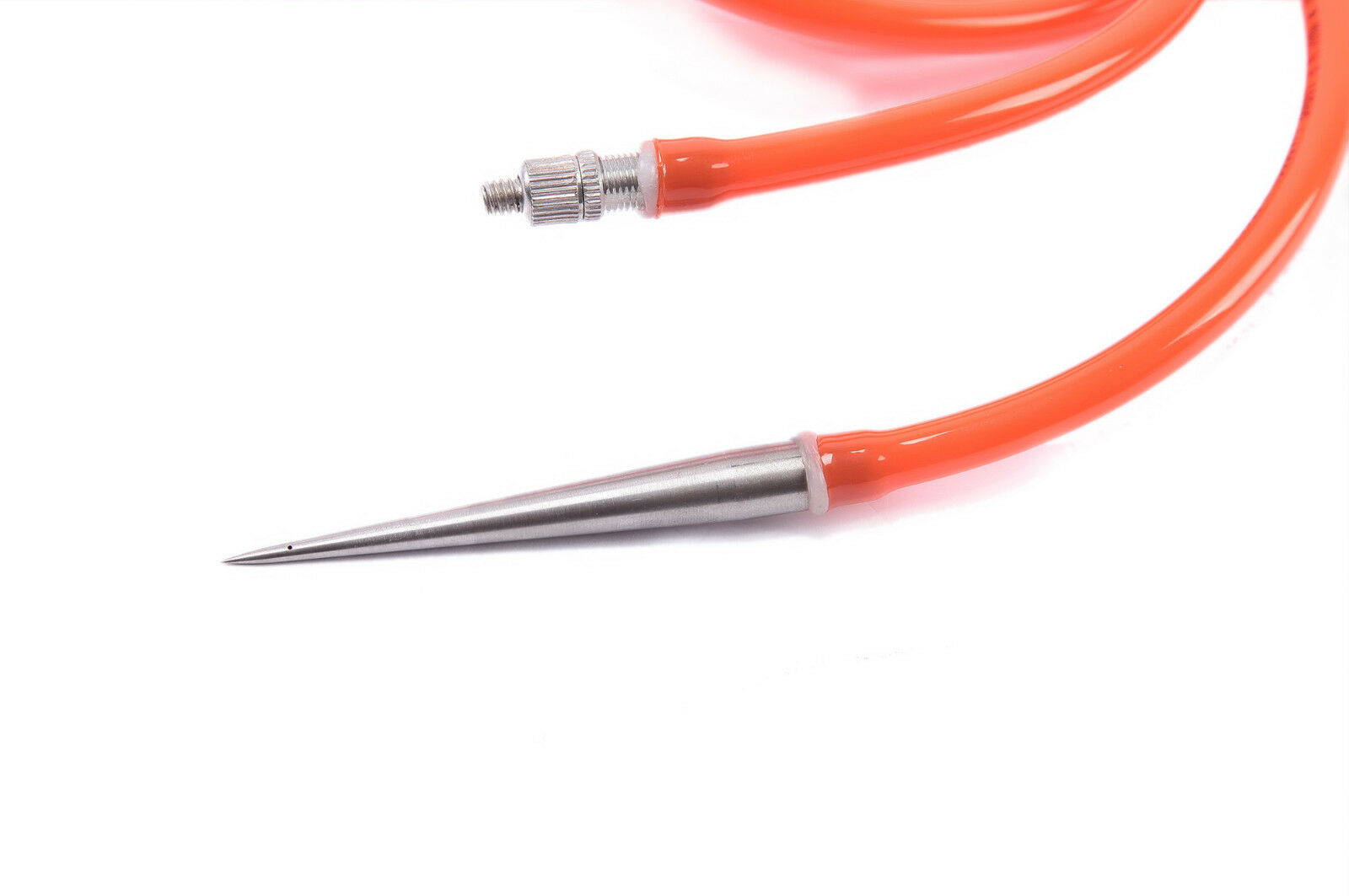

geomembrane air pressure detector membrane leak tester

$ 76.55

- Description

- Size Guide

Description

Geo membrane Air pressure tester is one of Lesite series attached with geo membrane welding machines ,which used for testing welding quality. Its working principle is when welding geo membrane central cavity filled with air under pressure to maintain a certain period after the gauge pointer remains unchanged weld quality is reliable. The product is simple to operate, easy to carry, reliable detection, especially for detection of the construction site of the geo membrane seam quality.1.Parameter

0~0.6Mpa

2.Operation

(1)The test pin is stainless steel hollow needle, it will break when improper use . So when the needle is inserted into the membrane testing in same direction but not left and right direction so as not to break the needle .

(2)When the temperature is below 15

degree

, the membrane turn hard not being easily inserted . In this case, the membrane can be heated manually by handle heater.

(3)Testing needle insertion depth depends on weld length and time-dependent leak .At longer time , you can slowly push the needle forwardly to ensure tightness between the needle and the membrane to prevent leakage of needle , to ensure the successful completion of testing.

(4)The test pin is properly connected with the air pump operation . Note the pump connector needs into the soft tube, which pressing on the black locker , and connecting the needle valve inside the folder to the inflatable mouth ( similar as bike inflatable ) .

(5)The test needle can be determined. Method is to use your fingers to suppress the pinhole . While testing needle being filled with certain air , it is normal if reading of pressure gauge keep same after a few minutes of reading the same normal.

(6)Being filled with certain air , if the pressure gauge reading remains unchangeable for some time , then weld quality standards.

3.Precautions

(1)Test pin should be properly and cleanly kept . Shall handled carefully to avoid damage.

(2)Generally the pressure of needle is appropriate at 3/ 4 of cap , not necessary full . The instrument should be checked regularly to ensure the accuracy..

4.Packing List

(1) pressure testing needle 1 set

(2) Manual 1copy